Supply chains are vital for businesses as they facilitate the flow of goods and services from raw materials to the end consumer, impacting efficiency, cost, customer satisfaction, and overall profitability. A disruption in the supply chain can throw a company’s operations into disarray, but also has serious impacts on customers. But supply chain disruptions seem to be more common than ever, posing increasing challenges for all industries. On April 3, Boise State University business and nursing students and faculty gathered with community members to explore supply chain issues at the spring 2025 Business Ethics Roundtable. The event was co-sponsored by the Boise State College of Business and Economics and the School of Nursing, and was hosted by Hansberger Endowed Chair in Business Ethics Ruth Jebe and DeMeyer Endowed Chair in Nursing Amy Spurlock. The dinner table discussions focused on the history of supply chain challenges faced by the healthcare industry, through a case study presented by Adrian Wengert, vice president of supply chain and procurement for St. Luke’s Health System.

Supply Chain Disruptors and Demands

Current business news is filled with discussions on major supply chain disruptions and the need to create resilience and flexibility in supply chains. Key disruptors include:

Extreme Weather Events and Climate

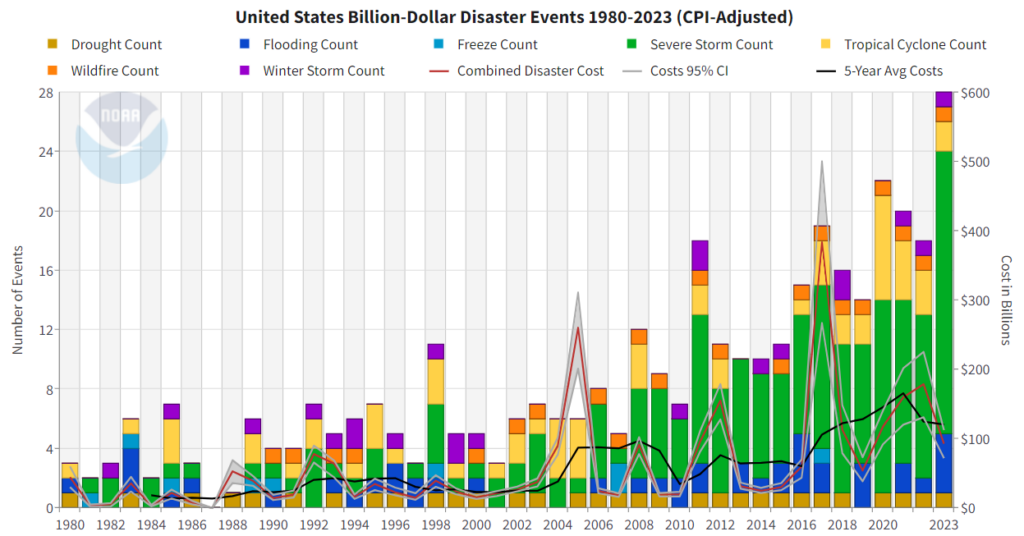

Extreme weather events are one of the primary risks for supply chains worldwide. These events can be anything from tornadoes to hurricanes to flooding to ice storms to droughts and can occur anywhere in any season. While we used to consider extreme weather to be “freak storms,” data shows that the rate of extreme weather events is on the rise. According to the report by Economics Impact, four decades ago, one occurred every four months; today, a billion-dollar extreme weather event occurs every three weeks. The overall trend makes extreme weather anything but unusual. These days, companies are even hiring meteorologists to provide accurate weather and climate forecasts to support their operations. The chart below given by climate.gov shows the increase in the rate of extreme weather in the United States from 1980.

Geopolitical Tensions

The global nature of modern commerce connects businesses to a complex network of supply chains, making business vulnerable to geopolitical instability. Recent events, like the war in Ukraine and rising tensions in the South China Sea show how much political issues can disrupt supply chains. Disruptions can take the form of tariffs and trade wars, port closures or customs delays, and sanctions.

Scarcity and Shortages

When there is competition for scarce resources, that competition can impact supply chain management. Supply availability, price fluctuations, and increased costs all affect a company’s ability to produce and deliver products and services. This is true whether the resource at issue is a primary product input, necessary product packaging, or labor.

Ethical and Sustainable Supply Chains

While supply chains face increasing potential for disruption, there are heightened demands for businesses to build responsible supply chains. Ethical and sustainable supply chains are crucial for minimizing environmental impact, ensuring fair labor practices, and promoting social responsibility. Companies are increasingly held accountable for sourcing materials responsibly, reducing waste, and supporting human rights, fostering long-term business viability, consumer trust, and a healthier planet for future generations.

Supply Chain Realities in the Healthcare Industry

Supply chain issues in the healthcare industry illustrate how these demands and disruptors play out in the real world. Adrian Wengert of St. Luke’s Health Systems recounted how industry history and practices resulted in a major product shortage in fall 2024.

In September 2024, Hurricane Helene hit the North Carolina coast, causing serious damage to a manufacturing plant owned by Baxter International, a primary supplier of hospital IV fluids. IV fluids might sound prosaic, but they are a class of critical supplies needed by healthcare providers to effectively treat patients with a variety of conditions. Baxter produces nearly 60% of all the IV fluids used daily in the U.S. With its plant out of production for nearly four months and extreme shortages of IV fluids, hospitals and health systems across the country had to cancel and/or postpone surgeries and procedures.

Shortages in the supply of IV fluids are not a new phenomenon; in fact, shortages date from the time of the second war in the Persian Gulf. Changes in the location of manufacturing plants leave a stretched supply chain in danger from extreme weather events. In 2017, a IV fluid equipment manufacturing plant which had relocated from Kansas to Puerto Rico for tax reasons, was hit by Hurricane Maria. Low profit margins and increased regulation of IV fluids have caused consolidation in the field. Currently there are only three major providers of IV fluids. So, when disasters arise, given the limitations to the supplies in normal circumstances, disruption wreaks havoc up and down the line.

Access to a strong and deep supply of IV fluids from across the three manufacturers is the ideal way to guarantee supply availability. However, the healthcare industry has evolved business practices that drive further complexity.

- Group Purchasing Organizations (GPOs) – Will allow health systems to only contract with one primary IV solutions manufacturer at a time

- Product Allocations – Health systems often are restricted to order no more than 75-90% of the total IV fluid bags required to take care of their patients to prevent hoarding and further destabilization of the manufacturing capacities.

- Product Backorders and Discontinuations – An increasing trend where manufacturers, sometimes with very little notice, cease production of various products needed by physicians and medical professionals. This requires clinicians to alter protocols or validate substitute products.

- Switching Costs – Contractual agreements for IV fluids are written to incentive the health systems to bundle the IV sets, accessories and IV pumps. If contractual compliance is not maintained or the contract is severed, penalties are in the millions of dollars by design.

With this background information, Roundtable participants were asked to consider several questions as part of redesigning how we think about supply chains. For example,

- How do hospitals build access to necessary supplies to maintain quality patient care?

- How do we make sure that small hospitals, who lack the purchasing power of large health systems, do not consistently fall victim to supply shortages?

- How do we include front line workers – in this case, nurses and other clinicians – in discussion about supply chain management?

- What are the pressures on these clinicians when supply chains are disrupted and how do they work to create alternate protocols to ensure patient care?

- Are we at a point where we need to recognize that volatility is a feature of supply chains, and plan for that?

Key Takeaways and Questions

As we navigate supply chain volatility, the healthcare industry’s experience presented some clear takeaways:

- In response to supply chain disruptions experienced during the COVID-19 pandemic, many hospitals have shifted from relying on a limited number of suppliers to diversifying their vendor base. For example, Saint Luke’s previously depended on a single vendor for critical supplies. Today, they have expanded their network to include 111 registered vendors, significantly enhancing their supply chain resilience.

- One of the questions raised was how hospitals and staff manage when they run out of supplies. An experienced nurse responded, explaining that in such situations, they must think creatively and adopt out-of-the-box solutions to ensure patient care continues. They often rely on alternative approaches and increase the frequency and depth of their observations to assess whether patients truly need items that are running low or no longer available. Ultimately, it comes down to careful observation, critical thinking, and strategic planning to manage patient care effectively, even with limited resources.

- One of the nurses participating in the roundtable highlighted how human emotions and preferences can influence the supply chain of specific healthcare items. She cited the example of butterfly needles versus straight needles for blood collection. Hospital staff often prefer butterfly needles due to their ease of use, especially for patients with small, fragile, or hard-to-access veins. This comfort and convenience lead to higher demand and increased ordering of butterfly needles. However, butterfly needles are approximately four times more expensive than straight needles, which significantly impacts the overall cost of healthcare supplies.

- Another important point raised during the discussion was the challenge of managing product shelf life and perishability in the healthcare industry. Unlike other sectors where bulk purchasing can be an effective way to prepare for disruptions, healthcare facilities are limited by the perishable nature of many medical supplies. Items such as medications, sterile instruments, vaccines, and diagnostic kits often have strict expiration dates and require specific storage conditions, making large-scale stockpiling impractical. The perishability of these supplies means hospitals must rely on a steady, just-in-time flow of fresh inventory to ensure patient safety and uninterrupted care. This continuous dependency places added pressure on maintaining a resilient, agile, and efficient supply chain.

- One of the nurses emphasized that frequent changes in medical products can significantly impact the hospital staff’s confidence. She pointed out that as the healthcare industry continues to evolve, and with supply chain disruptions and cyberattack issues becoming increasingly common, it is essential for both nursing schools and hospitals to proactively train staff to navigate these changes. Preparing students and professionals to be adaptable and resilient is crucial. They must be equipped not only to handle new tools and protocols but also to respond efficiently to unexpected situations while ensuring that healthcare operations continue to run smoothly.

- During the roundtable, Prof. Ruth Jebe introduced the concept of VUCA—an acronym used in the military to describe environments that are Volatile, Uncertain, Complex, and Ambiguous. She explained how modern militaries incorporate VUCA thinking into their strategic planning, allowing them to adapt quickly and effectively to ever-changing field conditions. Prof. Jebe emphasized the importance of applying this same framework to the healthcare supply chain. By embracing VUCA principles, hospitals and healthcare systems can become more agile and better prepared to respond to the dynamic, unpredictable challenges they face in today’s fast-evolving landscape.

- Participants noted that many U.S. supply chain issues are self-created, stemming from treating supply chains as isolated systems rather than integral parts of business operations. A key example was the relocation of an IV fluid manufacturing plant from Kansas to Puerto Rico for tax benefits. When Hurricane Maria hit Puerto Rico, it disrupted the entire U.S. IV fluid supply chain. This could have been avoided, as Kansas is less prone to such natural disasters. The discussion highlighted the need for risk-aware, strategic supply chain decisions.

- Business and nursing students discussed the value of sim-labs in providing hands-on experience with worst-case scenarios. It was suggested that business schools should incorporate simulation labs or practical learning opportunities where students can tackle real-world business challenges. This could be achieved by creating sim-labs or by partnering students with businesses for a few years, allowing them to observe, learn, and solve unforeseen issues. Such experiences would make students more adaptable and better prepared to face business challenges.

- The roundtable discussion concluded with a key takeaway on the importance of communication in business and operations to overcome challenges collaboratively. All participants agreed that involving managers and staff at all levels in communication about business operations and the supply chain is crucial. Frontline workers, such as nurses and other staff, should also be included in supply chain decisions. This ensures they are informed, aligned, and better equipped to respond effectively to unforeseen challenges and disruptions.

Final Thoughts

The supply chain disruption faced by the healthcare industry in 2024 is emblematic of the broader issues in supply chain management. Rather than viewing supply chains as steady processes only occasionally disrupted, we need to recognize that volatility is a feature – not a bug – of supply chains. That means we need to develop strategic plans based on volatility to better weather day-to-day supply issues and position ourselves to respond to heightened volatility.

Thanks to Amy Spurlock, the DeMeyer Endowed Chair in Nursing, and the Boise State School of Nursing for co-sponsoring the spring 2025 Business Ethics Roundtable. A special thanks to Adrian Wengert for generously sharing the story of St. Luke’s. If you are interested in participating in a Business Ethics Roundtable, please contact Perrine Blakely, Senior Development Director for COBE, at perrineblakley@boisestate.edu.